Schematic of Large-scale repeated loading laboratory setup

Description

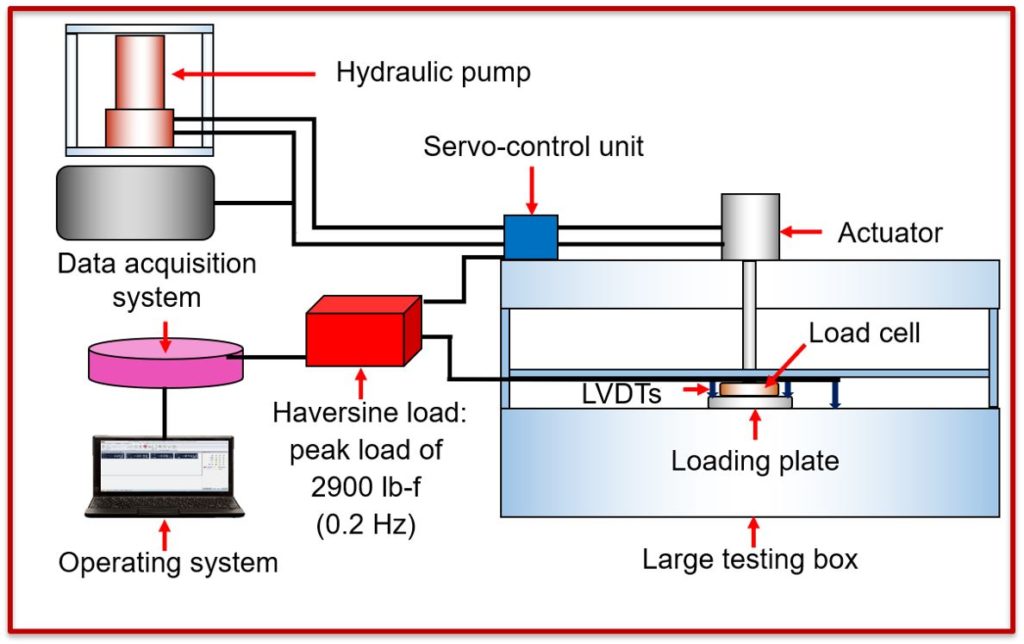

A large-scale test setup is available in the Center for Infrastructure Renewal (CIR), Texas A&M University, which was designed and constructed to facilitate a wide range of repeated and static load testing to evaluate the behavior and performance of the pavement section. The laboratory test setup consists of a large testing box, loading frame, accumulator, hydraulic pump, load regulator, data acquisition system, linear variable displacement transducers (LVDT’s), and load cells. The permanent deformations and resilient moduli of the test sections under traffic loading can be determined from the repeated load testing. Based on the standard failure criteria for the unpaved road, it is possible to determine the total number of load repetitions for each reinforced sections. Traffic benefit ratios can be estimated for comparison. It is also possible to conduct static load testing to determine the load-bearing capacities for different reinforced sections based on characteristic load-deformation curves.

Specifications

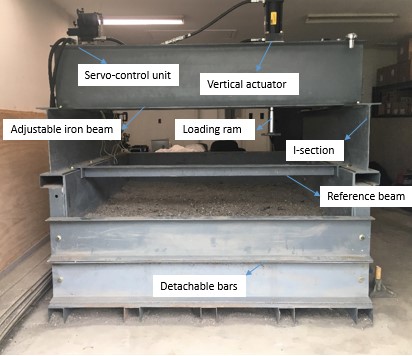

Large Testing Box

- The overall dimensions of the test box were 6.67 ft. long, 6.67 ft. wide, and 5.17 ft. high. The sides of the test box are fixed with 30-in. square steel plates. A reference beam is placed on the fixed plates to hold the LVDT’s, with the help of an adjustable magnetic holder. Two adjustable iron beams are bolted on the top of the I-sections to support the loading frame, which consisted of the loading frame and servo control unit.

Loading Frame

- The loading frame consisted of a servo control unit, a hydraulic actuator, and the load cell. The servo control unit is used to apply loads on the test section. The hydraulic actuator received the supplied hydraulic fluid pressure through the servo control unit and converted the hydraulic energy into loading forces (mechanical energy). The loading forces are applied through the loading ram of the vertical actuator in the center of the crosshead, which is attached to the load cell. The load cell is connected to the data acquisition system

Accumulator and Hydraulic Regulator

- The hydraulic fluid pressure is maintained in the accumulator and supplied through the hydraulic pump to the loading frame. An accumulator bottle is set up to keep the pressure regulated in the system and prevent the maximum pressure drop, as low-pressure prevents the system from achieving the maximum stress selected by the user. The accumulator bottle is connected to a fenner fluid power hydraulic pump with an A-C motor, which recirculated the fluid, by mechanical action, to generate a flow path and force it to the hydraulic system through a flow control.

Cyclic Load Regulator

- The cyclic load regulator consists of an electro-pneumatic transducer, return motion controller (RMC), and DC Power supply. It produces an electronic signal to the electro-pneumatic transducer, which helps to balance the forces. The RMC70 series one-axis and two-axis motion controllers regulate the frequency, the waveform, position, and magnitude of the system. The RMC70 series is a command-based program with two power control modes, including dual-loop-position-pressure algorithms and multiple feedback types.

Data Acquisition System

- The StrainSmart 8000-8 data acquisition system is set up to record the data from the load cell and displacement transducers (LVDT’s). It was connected to a computer via an Ethernet cable to provide easy operation of Micro-Measurements StrainSmart software.

Linear Variable Displacement Transducers (LVDT’s)

- High-resolution LVDT’s are available to measure the vertical deformation of the composite road section to the respectively applied load. The LVDT’s had displacement ranges from 0 to 4 inches

Load Cells

- 1 major (10,000 lb capacity) and 4 additional (1,000 lb capacity) load cells are also available with this system.

Publications

- Khan, Md Ashrafuzzaman, Nripojyoti Biswas, Aritra Banerjee, and Anand J. Puppala. “Performance of Geocell-Reinforced Recycled Asphalt Pavement (RAP) Bases in Flexible Pavements Built on Expansive Soils.” In Geo-Congress 2020: Geotechnical Earthquake Engineering and Special Topics, pp. 488-497. Reston, VA: American Society of Civil Engineers, 2020.

- Khan, Md Ashrafuzzaman, Nripojyoti Biswas, Aritra Banerjee, and Anand J. Puppala. “Field Performance of Geocell Reinforced Recycled Asphalt Pavement Base Layer.” Transportation Research Record 2674, no. 3 (2020): 69-80.

- George, Anu Muthumala. “UTILIZATION OF GEOCELL-REINFORCED RAP MATERIAL BASE LAYER IN FLEXIBLE PAVEMENTS: EXPERIMENTAL AND NUMERICAL STUDIES.” PhD diss., 2018.

- George, Anu M., Aritra Banerjee, Tom Taylor, and Anand J. Puppala. “Large-Scale Experimental Studies to Evaluate the Resilient Modulus of Geocell-Reinforced Reclaimed Asphalt Pavement Bases.” In Geosynthetics Conference, pp. 10-13. 2019.

- George, Anu Muthumala, Aritra Banerjee, Anand J. Puppala, and Manikanta Saladhi. “Performance evaluation of geocell-reinforced reclaimed asphalt pavement (RAP) bases in flexible pavements.” International Journal of Pavement Engineering22, no. 2 (2021): 181-191.