Description

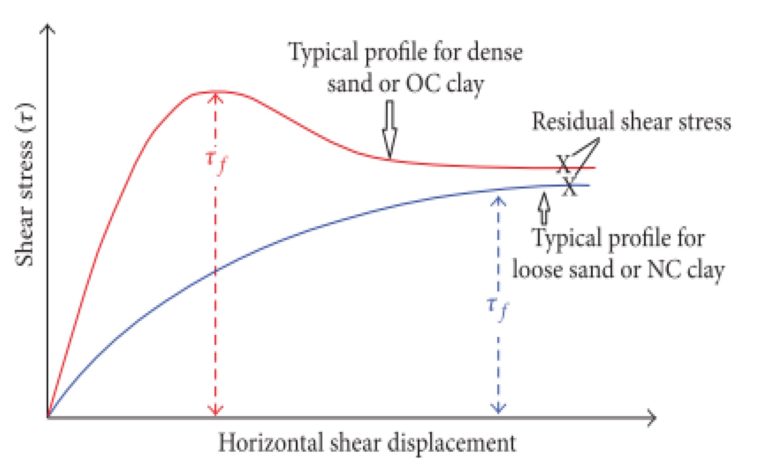

The direct shear (DS) (ASTM D3080/ D3080M) test is a popular test to determine the shear strength parameters (cohesion, c and internal friction angle, ϕ) because it is simple, easy to perform, and inexpensive. This test is useful when a soil mass is likely to fail along a thin zone under plane strain conditions. The sample container for a DS test is a horizontally split, open metal box, called a shear box. Soil is placed in the box and one-half of the box is moved relative to the other half in the horizontal direction. Failure is thereby constrained along a thin zone of soil on the horizontal plane.

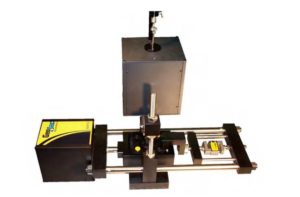

The DigiShear™ Automated Direct Shear Testing System is a computer controlled direct shear device that automates DS testing. It is a complete system incorporating GeoJacs (automated load actuators) for both vertical and horizontal loadings, four channels of 22-bit data acquisition, and all necessary sensors. Testing can be performed under closed loop control of deformation, load, or pressure. Specimens can be loaded and sheared in a variety of modes, including constant rate of deformation, constant rate of loading, or application of a series of step loads. . The DigiShear™ system automates the consolidation as well as the shearing portion of the test. Also, horizontal loading can be cycled during shear to determine residual strength.

Testing Ranges

- Load capacity

- Vertical: 2000 pounds

- Horizontal: 2000 pounds

- Speed: 0.000002 to 0.2 in/min

- Horizontal Travel: ± 0.5 in

- Specimen Rings: 2.5 in diameter

Material Properties

The determination of the cohesion, (c) and internal friction angle, (ϕ) is commonly accomplished by the direct shear test. The Mohr-Coulomb failure envelope (s) is a straight line, as defined by Coulomb (1776) and is represented by the equation s= c+ σ tan ϕ.

Field Applications

- Design of footing, embankments and foundations

- Analysis and design of slopes

- Design of MSE retaining walls

- Analysis of soil-geosynthetic interactions

- Evaluation the engineering properties of gas hydrate-bearing sediments

Publications

- Puppala, Anand J., Pinit Ruttanaporamakul, Tejo V. Bheemasetti, and Ali Shafikhani. “Laboratory and field investigations on geofoam.” Journal of Pipeline Systems Engineering and Practice 10, no. 1 (2019): 04018036.

- Nguyen, H. M., B. H. Fellenius, A. J. Puppala, O. C. Nguyen, and T. V. Bheemasetti. “Results of static loading tests on single piles and on pile-supported LPG Tanks.” Geotechnical and Geological Engineering 36, no. 6 (2018): 3811-3822.

- Acharya, Raju, Aravind Pedarla, Tejo V. Bheemasetti, and Anand J. Puppala. “Assessment of guar gum biopolymer treatment toward mitigation of desiccation cracking on slopes built with expansive soils.” Transportation Research Record2657, no. 1 (2017): 78-88.

- Puppala, Anand J., Sireesh Saride, Raja V. Yenigalla, Bhaskar CS Chittoori, and Ekarut Archeewa. “Long-term performance of a highway embankment built with lightweight aggregates.” Journal of Performance of Constructed Facilities 31, no. 5 (2017): 04017042.

- Cai, Guojun, Songyu Liu, and Anand J. Puppala. “Evaluation of geotechnical parameters of a lagoonal clay deposit in Jiangsu Lixia River area of China by seismic piezocone tests.” KSCE Journal of Civil Engineering 20, no. 5 (2016): 1769-1782.

- Vipulanandan, Cumaraswamy, Anand J. Puppala, M. Jao, M. S. Kim, H. Vasudevan, P. Kumar, and Y. L. Mo. Correlation of Texas Cone Penetrometer test values and shear strength of Texas soils: technical report. No. FHWA/TX-08/0-4862-1. 2008